Brand:GRAND

Classification:PRODUCTS

Address:Royal Oak Industrial Estate, Daventry, Northamptonshire, UK

Order Hotline:+44 7719 312962

Valve features

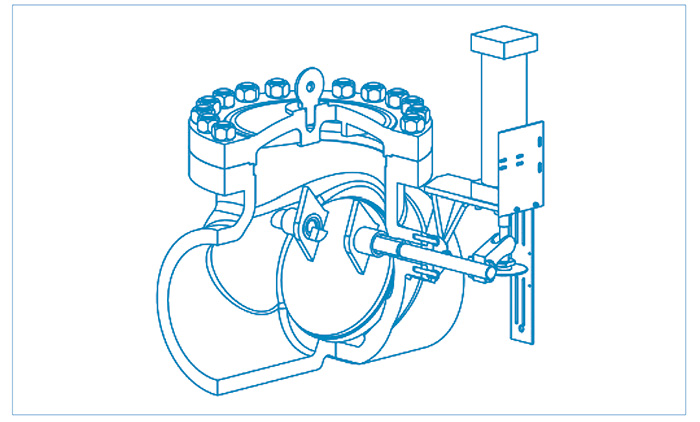

GRAND swing check valve can be applied in the environment that allows only one-way flow to prevent the backflow from damaging equipment .

The swing check valve can be easily opened to enable the fluid to pass through completely, thus reducing the pressure drop or disturbing flow.

During the service period, it can completely prevent damage to the valve seat, valve plate, shaft sleeve and guide ring, it would not damage the machine or result in a water hammer at the moment of fluid stop due to the quick closing mechanism.

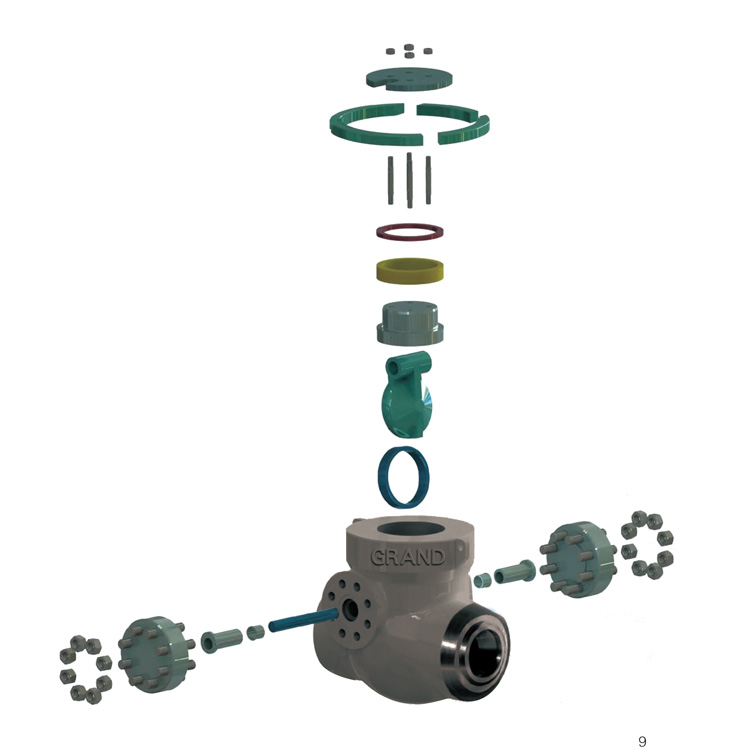

GRAND produces pressure seal and bolted bonnet swing check valves, which are widely used in different fields.

■ Pressure class (ASME): 900—4500

■Size: 2"—24"

■ Valve body and bonnet: Made of carbon steel, alloy steel and stainless steel.

The thick valve body wall can assure tightness and shape protection.

Post machining of the valve seat and other surfaces can assure a good tolerance fit of all components.

■ Valve seat: The structure of inclined valve seat greatly improves its performance and reduces pressure drop.

■ Valve plate: The valve plate is self-aligning, which is formed by the special matching of the valve plate and the shaft sleeve to achieve the perfect seat-surface.

■According to the standard design of ASME B16.34, the seat with a large inclination angle and the travel structure with a small opening angle are adopted to realize quick valve closing when the medium flows backward.

■ With spring reset pneumatic or hydraulic valve actuator, the valve can be closed faster.

■ When DN≥300 mm, the disc balance weight is increased, the impact force on the valve seat is reduced, and the service life of the valve is prolonged.

■ The pneumatic extraction check valve can adapt to various harsh working conditions, with excellent quick response performance and good control interface, long service life, and valve closing time≤1.5s.

■ The special design of the hydraulic extraction check valve can speed up the closing of the valve, with the closing time ≤ 3 seconds.

■ The sealing surface of the valve disc and the valve seat are all built-up welded by Stelli). (The sealing surface has high hardness with excellent wear resistance, corrosion resistance, high temperature resistance and anti-scratch resistance,so that the valve has a long life.)

■ The shaft is made of high-quality nitriding steel by tempering and nitriding heat treatment, with high surface hardness and good scratch and corrosion resistance.