Brand:GRAND

Classification:PRODUCTS

Address:Royal Oak Industrial Estate, Daventry, Northamptonshire, UK

Order Hotline:+44 7719 312962

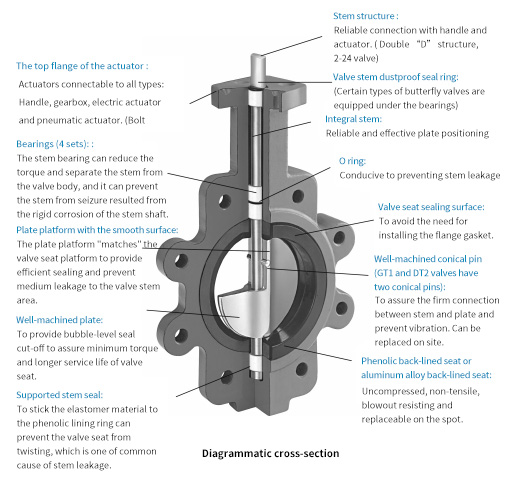

Valve features - high-pressure butterfly valve

■When the valve is open up to 90°, the gap between the valve plate sealing surface and the valve seat sealing surface is much larger than that of single eccentricity.

■ These two eccentric structures produce a cam-like effect. When the valve is open, the valve plate can be away from the valve seat withouta large pulling force.

■ When the valve plate is removed from the valve seat, the valve plate will no longer contact with the valve seat, which reduces the friction between the valve plate and the valve seat, reduce the torque time required for valve opening and extend the valve life.

■ The design of the valve body conforms to ANSI design standard to assure sufficient the safety and strength of the integralcast valve body.

■ The core of the three-eccentric metal hard seal butterfly valve is an elliptical cone overlaid with wear-resisting hard alloy on the surface.

■ The three-eccentric compound sealing structure has the seat sealing surface formed by valve body overlaid welding and the sealing ring is made of stainless steel and elastic material.

■Geometrically,the valve seat and seal ring are used in the whole opening and closing travel of the valve to eliminate wear and leakage.

■ The three-eccentric butterfly valve has very low torque and long life due to the friction between the valve seat and the sealing surface of the valve plate is almost zero.

■ The unique design of three-eccentricities makes it an ideal hard-sealed valve for high temperature, high pressure, toxic and harmful media

Valve features - low-pressure butterfly valve

Overview

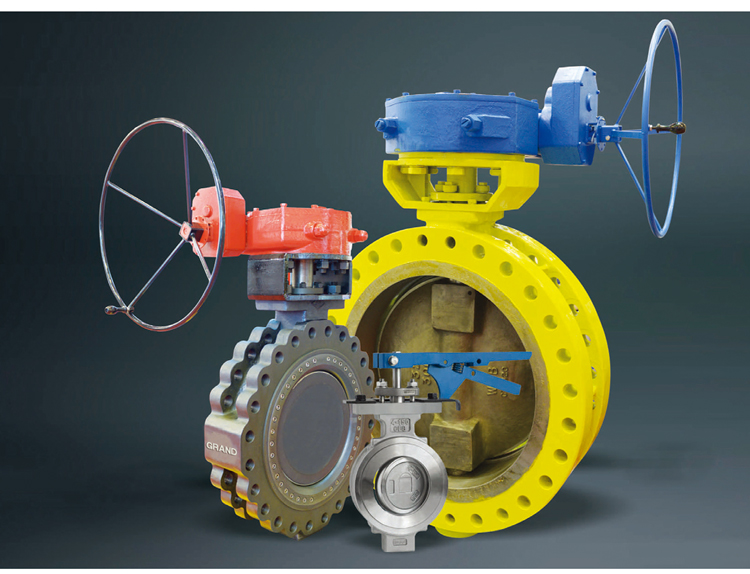

GRAND butterfly valve has always been the leader of the angle travel valve market. As a supplier for high-quality products with competitive price, we are well-received by users. Our goal is to exceed the industrial requirements and meet the needs of users.

We are committed to providing products that meet a wide range of application requirements. By developing new products and improving existing designs, we have continuously improved our production lines to provide our customers with the best products on the market.

We have a complete production line of rubber-lined butterfly valves, which can provide you with reliable products as required. We have our own factories for valve design and manufacturing and can guarantee the product quality.

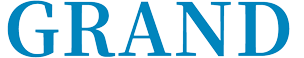

GRAND butterfly valve integrates quality control with the GT-series butterfly valves. These butterfly valves are characterized by cylinder seats and well-machined parts lined with a phenolic aldehyde or aluminum alloy on the back and can assure durable reliable operation.