Brand:GRAND

Classification:PRODUCTS

Address:Royal Oak Industrial Estate, Daventry, Northamptonshire, UK

Order Hotline:+44 7719 312962

Valve features

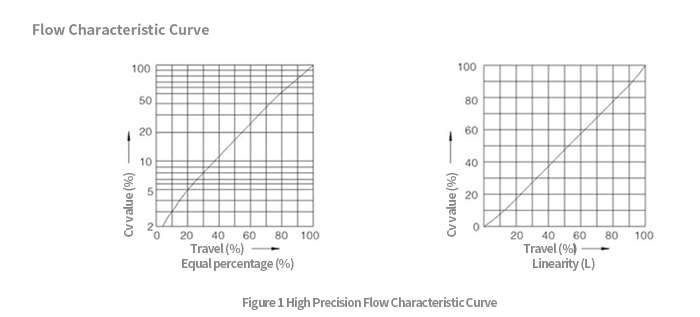

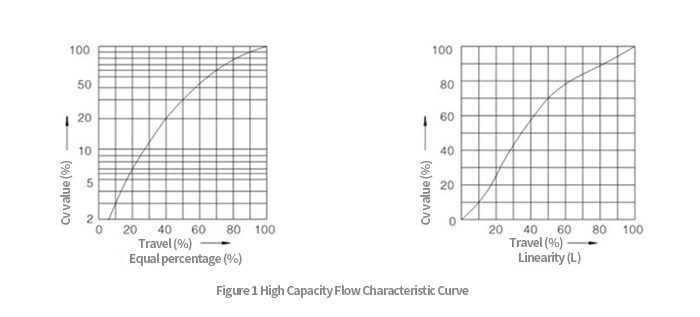

Fast opening/linearity/equal percentage

Valve structure

Select different structures according to different working conditions

Sleeve single seat valve/double seat valve/multi-stage pressure reducing labyrinth valve

Design and manufacturing standards

ASME B16.34 API 602

Connection mode

Butt Weld/flange--ASME B16.25

Technical parameters

Size: 1”-24”

Pressure rating: ANSI150—2500LB

Materials: WCB/WC9/C12A/A105/F22/F91, etc.

Operating mode: Electric/pneumatic/electric hydraulic

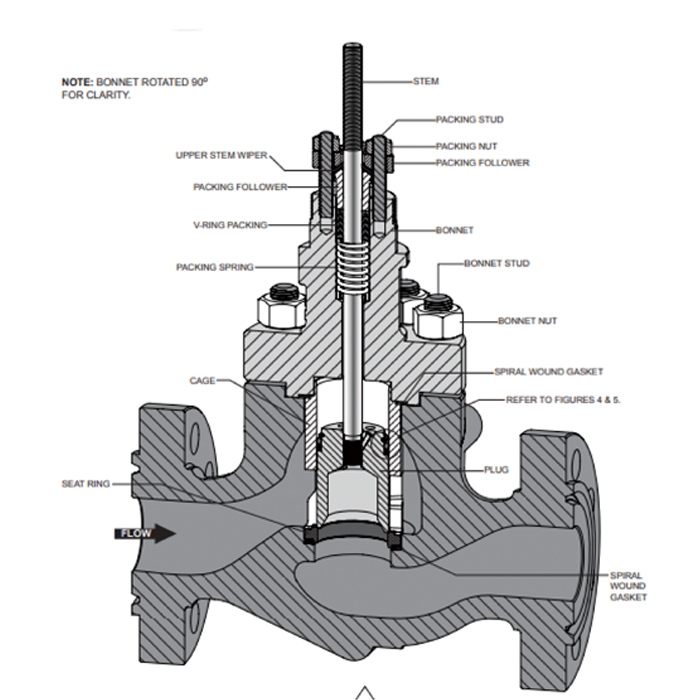

Sleeve single-seat control valve

Overview

GC-101 single-seat control valve has small volume and simple structure. The Type-S straight-through valve body with the latest low flow resistance design create a large internal cross-sectional area, enabling large flow rate, low pressure drop and small fluid loss. The embedded valve seat is convenient for replacing, and the flexible sealing form can be provided as required to reach the zero leakage standard.

GC-101 single-seat control valve is suitable for high-pressure and high-pressure differential flow control,which only needs a small driving force can achieve stable regulation. It is widely applied in flash cavitation caused by high pressure differential.

With a mature design concept, advanced production management, perfect service system, and GRAND will provide the users with high-performance, high-quality, high satisfaction control valve overall solution.

The GC-101 sleeve single-seat control valve is manufactured and inspected in strict accordance with ASME and API standards, and can also be specially manufactured according to the process requirements on site.

Main features

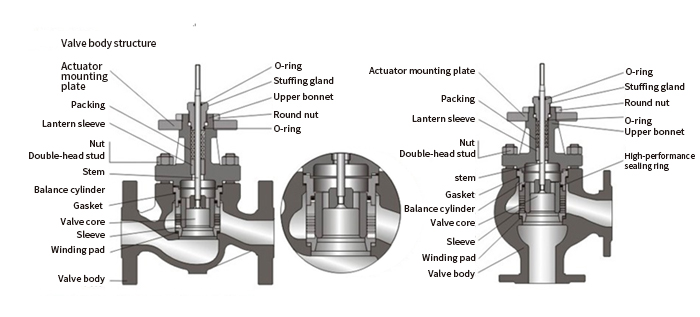

Modularization of overall structure design

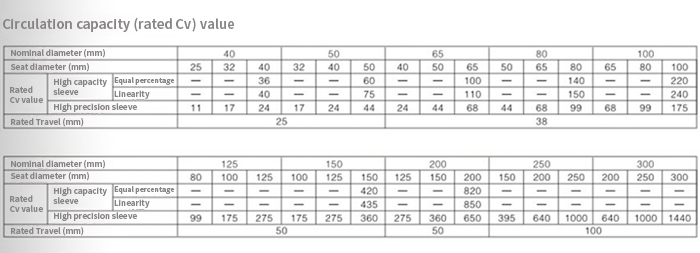

The same one valve body is equipped with a variety of structural internals to meet different requirementsworking conditions.

The valve body structure adopts the design concept of fluid mechanics

Just only need to change the sleeve in the case of the large flow rate, low pressure drop loss and changing flow capacity or flow features.

Safe and reliable double seal of stem structure

With a variety of stuffing box design, different types of packing and their combinations can be matched different applications.

Standard valve stem packing seal adopts the double-sealing structure of the packing seal ring to assure no leakage of the medium. More safe and reliable double packing seal and bellows seal can also be selected.

The precision technology reduces operation loss

The stuffing box, valve stem and other parts are all hardened on the surface. In addition, the most advanced hydraulic hardening mirror processing technology is used to make its surface smooth to achieve mirror effect, improve the corrosion-resistance of dynamic sealing parts, and reduce the friction between the valve stem and the packing.

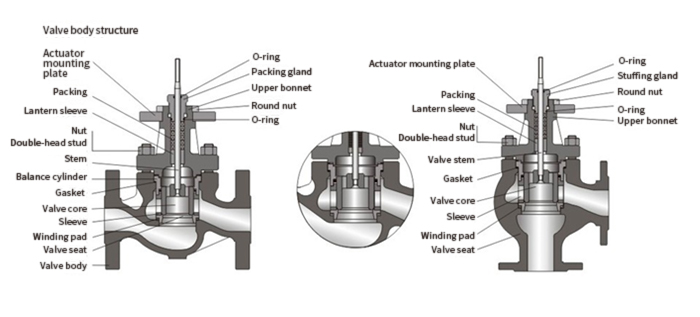

Sleeve double-seat control valve

Overview

GC-201 sleeve double-seat control valve has small volume and simple structure. Adopting the double-seat structure of sleeve-guide fluid pressure balance, and the latest low flow resistance design of Type-S straight-through valve body, the valve can achieve large flow, low pressure drop loss, high regulation accuracy, high dynamic stability, and low noise. The embedded valve seat is convenient for replacing, and the flexible sealing form can be provided to reach the zero leakage standardaccording to the needs.

GC-201 sleeve double-seat control valve is suitable for high temperature, low temperature and high pressure differential fluid situation,which only needs a small driving force to achieve stable regulation.Thisvalve is widely applied in when the seat leakage is not strictly required in the process and where higher pressure fluid is controlled.

With a mature design concept, advanced production management, perfect service system, GRAND can provide the users with high-performance, high-quality, high satisfaction control valve overall solution.

The GC-201 sleeve double-seat control valve is manufactured and inspected in strict accordance with ASME and API standards, and can also be specially manufactured according to the process requirements on site.

Main features

Modularization of overall structure design

The same one valve body is equipped with a variety of structural internals to meet different requirements working conditions

The valve body structure adopts the design concept of fluid mechanics

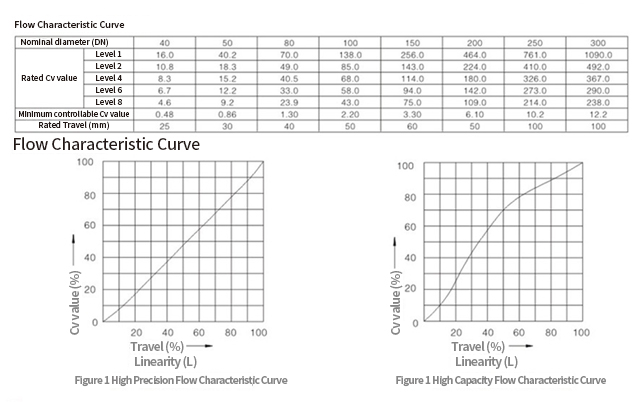

Only need to change the sleeve in case of the large flow rate, low pressure drop loss. Changing circulation capacity or flow features. Multi-CV values can be selected for the same one specification.

Safe and reliable double seal of stem structure

With a variety of stuffing boxes, different types of packing and their combinations can be matched to realize different applications.

The standard valve stem packing seal adopts the double sealing structure of the packing seal ring to assure no leakage of the medium. More safe and reliable double packing seal and bellows seal are also optional.

The precise manufacture can reduce operation loss

The stuffing box, valve stem and other parts are all hardened on the surface. In addition, the most advanced hydraulic hardening mirror processing technology is used to make its surface smooth to achieve mirror effect, improve the corrosion-resistance of dynamic sealing parts, and reduce the friction between the valve stem and the packing.

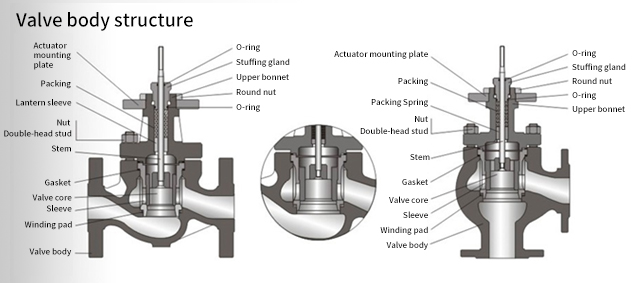

Labyrinth type multistage pressure reducing control valve

Overview

GC-301 labyrinth type multistage pressure reducing control valve adopts a fluid pressure balance single-seat structure with unique labyrinth type, multistage plate stack, and multistage sleeve guide. Multistage pressure drop can effectively control the speed of fluid flowing through the valve internals, and solve the noise and cavitation, etc. Enabling accurate control, stable operation and long service life.

Applicable to harsh cases with high temperature, high pressure or high pressure difference and other fluids.

With a mature design concept, advanced production management, perfect service system,GRAND can provide the users with high-performance, high-quality, high satisfaction control valve overall solution.

The GC-301 labyrinth multi-stage pressure reducing control valve is manufactured and inspected in strict accordance with ASME and API standards, and can also be specially manufactured according to the process requirements on site.

Main features

The valve body structure adopts the design concept of fluid mechanics

Only need to change sleeve in case of the large flow rate, low pressure drop loss,changing flow capacity or flow features

Safe and reliable double seal of stem structure

With a variety of stuffing box design, different types of packing and their combinations can be matched to realize different applications.

The precise manufacture can reduce operation loss

The stuffing box, valve stem and other parts are all hardened on the surface. In addition, the most advanced hydraulic hardening mirror processing technology is used to make its surface smooth to achieve mirror effect, improve the corrosion-resistance of dynamic sealing parts, and reduce the friction between the valve stem and the packing.

Anti-clogging—The labyrinth disc has the same cross-sectional area of the inlet and outlet. Large particles cannot enter, and small particles will not get stuck in the flow path; The disk flow path is round, so that there is no dead zone at the corners to ensure no impurity accumulation.

Anti-scour--after multistage disc decompression, the medium flow rate is significantly reduced, reducing the impact on the sealing surface

Low noise--after multistage decompression, the flow rate of fluid is significantly reduced, and the noise is greatly reduced at the same time.